Quality Control

Kioxia Group considers that one of its most important mission is to provide customers with safe and reliable products. Accordingly, we are always striving to manage and improve product quality. In addition, we ensure our products are safe to use and secure, and disclose information regarding product quality to our customers.

Kioxia Group Comprehensive Quality Assurance

Kioxia Corporation aims to benefit society by providing high-quality, safe, and functionally advanced products and services that meet customer expectations, while complying with all relevant laws and regulations.

Quality Control Policy

Kioxia Corporation has set out its fundamental approach to quality control within our Quality Control Policy.

Standards of Conduct during Quality Assurance

- We engage in quality assurance from our customers’ point of view.

- We observe relevant laws and contracts and respect the rights of customers and third parties.

- We deploy quality control systems aimed at achieving 100% quality.

- We ensure that all of our departments and employees follow our quality control policies.

- We aim for constant improvement by investigating the root causes of process failures and conduct through risk analysis in order to prevent any re-occurrence.

- We collect, analyze and appropriately disclose information with the aim of preventing quality issues.

Standards of Conduct regarding Product Safety and Product Security

- We observe both Japanese and overseas laws and regulations governing product safety and product security.

- We collect, and proactively disclose, a wide range of information about any product issues that arise.

- We immediately report any product issues to the authorities concerned in accordance with relevant laws and regulations.

- We promptly inform customers when the need to recall and repair products arises.

- We educate our customers and provide alerts and warnings in order to help them use our products in a safe manner.

- If an accident should occur, we carry out a thorough analysis of the causes and take necessary measures to prevent it from recurring. We also strive to prevent accidents by predicting risk at the design stage.

- We strive to eliminate vulnerabilities from products prior to shipment.

- We collect a wide range of information on product vulnerabilities in order to reduce risk.

- We implement product security measures on a broad scale in cooperation with the relevant organizations.

Promoting Quality Control

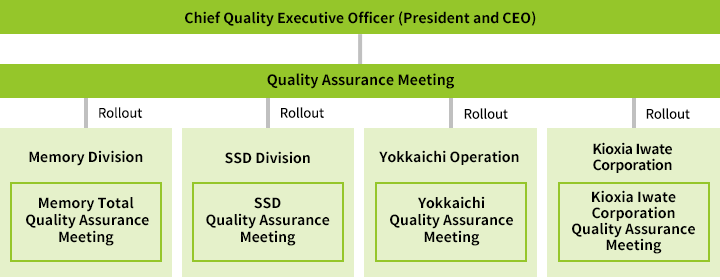

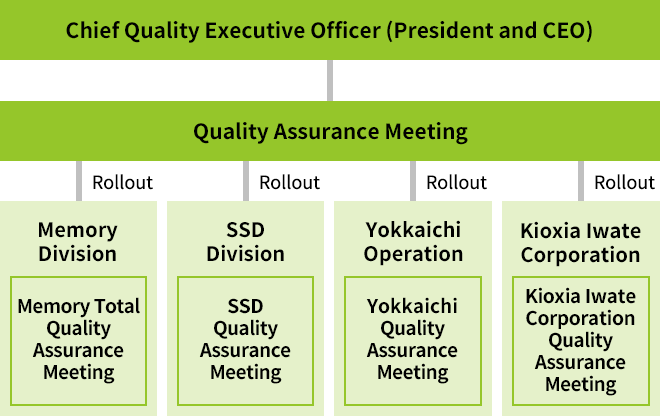

Kioxia Corporation has established a quality management system throughout its entire product process from planning and development to sales and customer service. Chaired by the President and CEO, who is also the Chief Quality Executive Officer, a Quality Assurance Meeting is held twice a year during which the Executive Officer in charge of quality, vice presidents of relevant departments, technology executives, general managers, and senior managers discuss and decide on key quality policy issues. The participants also evaluate the appropriateness and validity of quality management and risk containment measures. We communicate decisions made during these meetings to business divisions and ensure they are implemented.

Quality Control Processes & Responsibilities at Kioxia Corporation

Formulating Responses to Product Issues at Kioxia Corporation

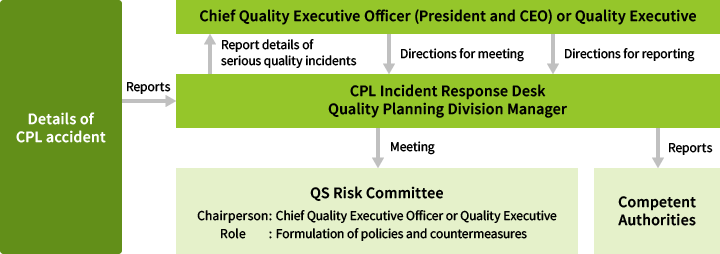

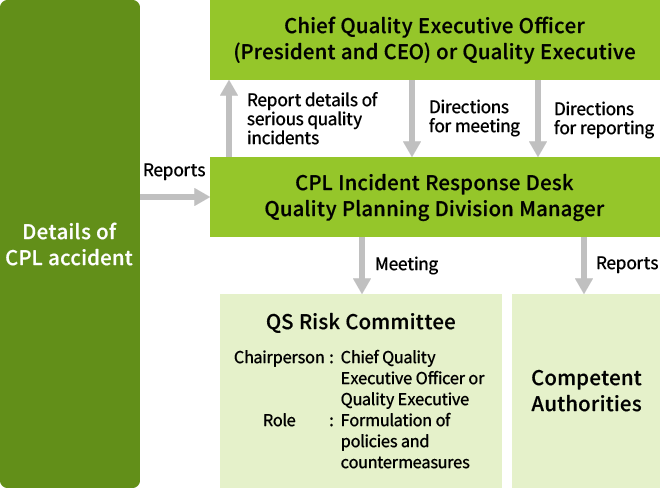

Information on issues involving products in the market is collated by the President and CEO of Kioxia Corporation, who is also the Chief Quality Executive Officer, or the Executive Officer in charge of Quality, through what we call the CPL¹ Incident Response Desk. Any issues are referred to the Quality & Safety Risk Committee, which will decide on any action that may be required.

No serious quality incidents occurred in FY2024.

- 1 CPL: An abbreviation combining CL (contractual liability) and PL (product liability)

Product Issue Response Processes & Responsibilities at Kioxia Corporation

Quality Management System (QMS)

Kioxia Group manufacturing sites and related facilities have obtained ISO 9001 certification, the international standard for quality management systems. We are implementing continuous improvements throughout the Group in accordance with the seven QMS principles on which ISO 9001 is based in order to enhance the effectiveness of these systems. Kioxia Corporation has also acquired IATF 16949 certification, the international standard for quality management systems specific to the automotive industry.

Improving Design Quality

In order to improve product quality at the design stage, Kioxia Corporation conducts product design reviews and quality reliability assessments by means of certification testing. We also conduct what we call Failure Mode and Effects Analysis (FMEA) on our design activities in order to prevent defects from reaching upstream. The aim of FMEA is to enhance quality by anticipating the risks and effects of failures or defects, known as failure modes, targeting product design and processes in the early stages of development. We strive to improve the reliability and safety of our products and services by implementing practical training to broaden the base of FMEA.

Improving Manufacturing Quality

Furthermore, at Kioxia Corporation, FMEA is used to identify the risk of quality issues and determine those that need to be managed as a priority. The capacity of each manufacturing process is analyzed and improvements are implemented on areas found to have low process capabilities. A method known as Statistical Process Control is deployed during efforts to stabilize or improve manufacturing quality.

Disclosure of Information on Quality

Kioxia Corporation discloses information regarding product quality on its website.

- Quality Guidelines

- Reliability Handbook

- Handling Precautions and Requests

- List of Abbreviations

Quality Education

Kioxia Corporation has created its own in-house curriculum and conducts education and training for engineers in order to improve design and manufacturing quality. Basic training is conducted throughout the year, including an introduction to quality assurance, contract liability and product liability (including the Product Liability Act), statistical quality control, and quality management systems, along with special training on topics such as QC7 tools,² FMEA/DRBFM,³ failure studies, and why-why analysis.

- 2 QC7 tools: A combination of seven techniques used in quality control to analyze the current situation. Specifically, pareto charts, characteristic factor diagrams, histograms, graphs, check sheets, scatter plots, and control charts.

- 3 DRBFM (Design Review Based on Failure Mode): A method of preventing quality defects that prioritizes design changes and modifications when conducting risk analyses.