Japan Audit and Certification Organization for Environment and Quality (JACO)

Health and Safety

For Kioxia Group to achieve sustainable development in harmony with society, the physical and mental well-being of each employee serves as an important foundation for our business activities.

Kioxia Group has established health and safety as priority areas of focus in terms of ensuring the Group’s medium- to long-term growth (what we call Sustainability Materiality), and we strive to create a safe and comfortable working environment for all employees and others involved in our business.

Health and Safety Policy

Kioxia Group’s senior managers in Japan all pledge to ensure health and safety across our operations, a pledge that is shared with all employees. Kioxia Corporation established its Basic Policy for Safety and Health at the time of the company’s foundation in 2017, and reviews the policy annually to ensure it continues to meet the needs of the times. Based on Kioxia Corporation’s Basic Policy, Kioxia Group in Japan has subsequently formulated its own policy and is accordingly implementing a range of health and safety initiatives.

Kioxia Group companies overseas implement employee health and safety initiatives in accordance with the laws and regulations of their respective countries and regions.

Promotion of Occupational Health and Safety (OHS)

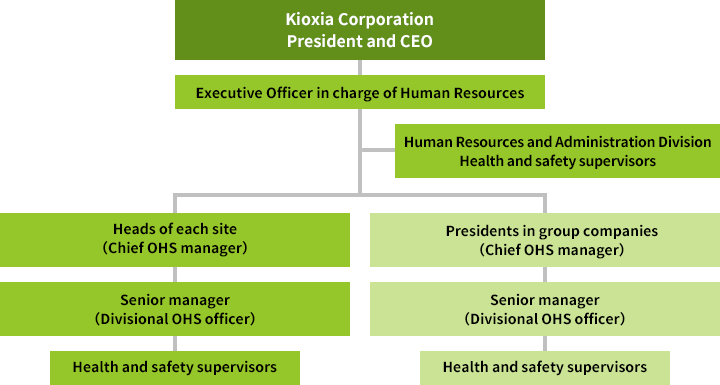

Kioxia Group in Japan deploys health and safety supervisors within the Administration Division of each group company to promote health and safety activities among employees. They report periodically on health and safety matters to the president of each group company. The Health and Safety Officer of the Human Resources and Administration Division of Kioxia Corporation summarizes these reports and shares the summaries with the President and CEO, and the Executive Officer in charge of Human Resources.

Organizational Structure for Health and Safety Management at Kioxia Group in Japan

OHS Management System

Kioxia Group has obtained the occupational health and safety management systems certification (ISO 45001:2018) for its manufacturing and R&D sites. As it moves to comply with the requirements for this certification, the Group is making efforts to continuously reduce health and safety risks through risk assessment and compliance with relevant laws and regulations, and is making its health and safety management measures more visible.

Kioxia Group is also committed to ensuring health and safety are maintained throughout day-to-day activities, involving both group companies and their employees. Our efforts include the creation of small workplace groups, which undertake a variety of activities on an ongoing basis. These activities encompass workplace improvement programs, education and training to increase risk awareness among employees, and monitoring to ensure that appropriate practices are being followed. We integrate these activities into our implementation of health and safety management based on ISO 45001 standards.

Acquisition of ISO 450001:2018 Certification

* Table can be scrolled horizontally.

|

Name of Company |

Certified Body |

Certificate Expiry Date |

Approval Certificate No. |

|---|---|---|---|

|

Kioxia Corporation |

|

March 28, 2028 |

WC18J0004 |

|

Solid State Storage Technology Corporation |

DNV |

November 23, 2027 |

183447-2015-ASA-RGC-RvA |

Key Health and Safety Initiatives at Kioxia Group in Japan (FY2024)

* Table can be scrolled horizontally.

|

Category |

Details |

|---|---|

|

Health and Safety |

|

|

Safety |

|

|

Health |

|

1 Periodic reports to the President and CEO of Kioxia Corporation about relevant activities underway at Kioxia Group in Japan

2 Workplace engagement: encouraging a positive and fulfilling attitude toward work among employees.

Health and Safety Awareness Raising and Education

Kioxia Group in Japan endeavors to enhance our employees’ understanding of the need for health and safety measures and for supportive behavior. On top of the training specified in the Industrial Safety and Health Act, we implement education programs for employees who are newly appointed to health and safety-related posts, as well as for mid-career employees in those positions. We also run practical training programs devised by individual operational sites.

Key Health and Safety Training Results at Kioxia Group in Japan (FY2024)

* Table can be scrolled horizontally.

|

Type of Training |

Ratio of Participation:No. of Participants/No. of Eligible Employees |

|---|---|

|

Training related to job promotion (health and safety) |

100% (177 / 177) |

|

Mental health training |

100% (16,735 / 16,735) |

|

Post-recruitment training (health and safety, road safety, etc.) |

100% (1,813 / 1,813) |

|

Various types of training based on the Industrial Health and Safety Act |

100% (1,424 / 1,424) |

|

Competence training |

100% (618 / 618) |

Each work site also conducts its own training in addition to the activities listed here.

Workplace Accidents

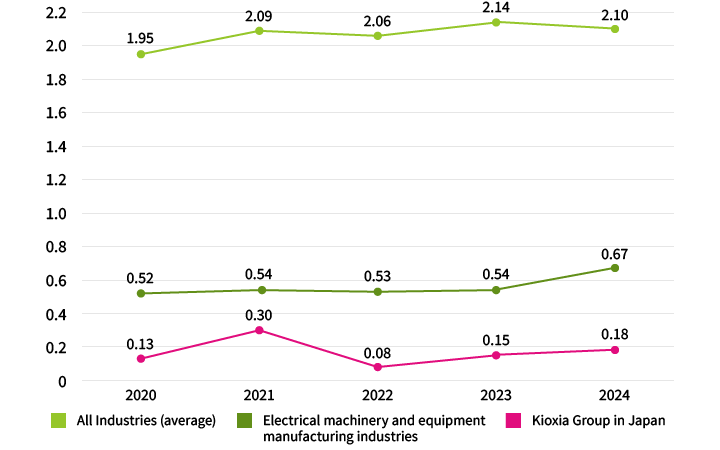

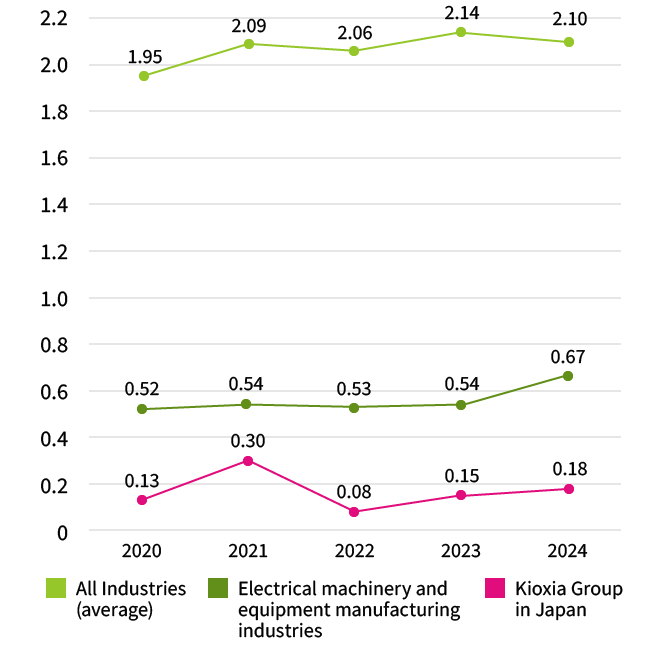

Kioxia Group in Japan strives to minimize the number of workplace accidents and monitor any occurrences. We use the “frequency of injuries resulting in lost working days” as an indicator of these efforts. In 2024, the frequency rate was 0.18, which was below the average rate of 0.67 in the electrical machinery and equipment manufacturing industries.

Kioxia Group in Japan will continue to implement further measures to prevent workplace accidents. As a top priority, risk assessments are conducted for all workplaces and tasks, focusing on operations where there is a high risk of serious injury or illness, as well as on the handling of hazardous or harmful chemical substances. In addition, we systematically manage and reduce risk by reviewing work methods, identifying and eliminating specific risks, renovating facilities, and providing education and training to employees.

Frequency of Injuries Resulting in Lost Working Time at Kioxia Group in Japan3

- 3 Frequency = Number of casualties due to work-related accidents / Total actual working hours x 1 million. Figures for all industries and the electrical machinery and equipment manufacturing industries are collated from the results of the “Survey of Industrial Accidents” conducted each year by the Ministry of Health, Labor and Welfare.

Health Management

As the environment in which Kioxia Group conducts business continues to change dramatically, we have been working on the implementation of health and safety measures for our employees, an investment which we see as essential for the future of the Group and the development of society (investment for health).

Kioxia Holdings Corporation issued its “Kioxia Group Health Management Declaration” in April 2023.

Kioxia Group Health Management Declaration

We firmly believe the health of our employees is essential in order to achieve our mission of “uplifting the world with ‘memory,’” and consider this to be one of our most important areas of management focus. We will continue to promote health management, aiming to improve the health of every employee in order to continue to create value for society through “memory” technology.

April 1, 2023

Nobuo Hayasaka, President and Chief Executive Officer,

Kioxia Holdings Corporation

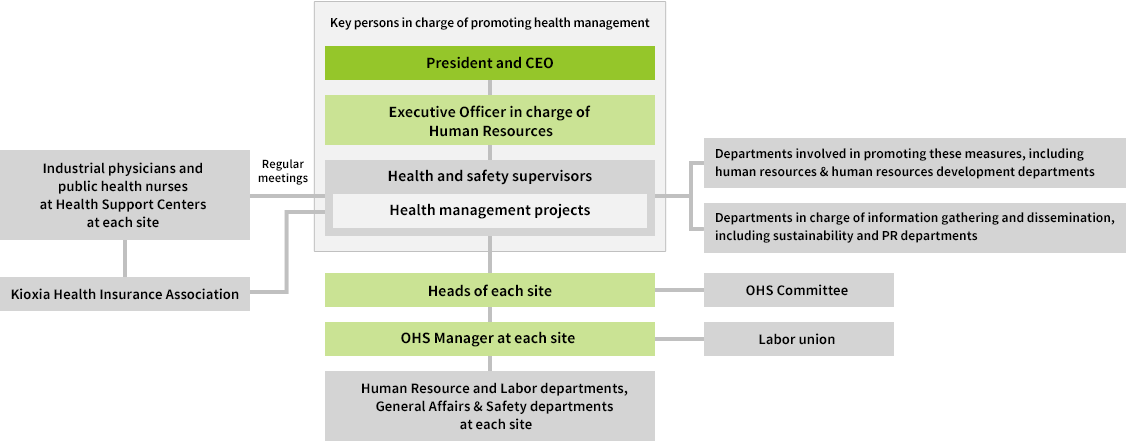

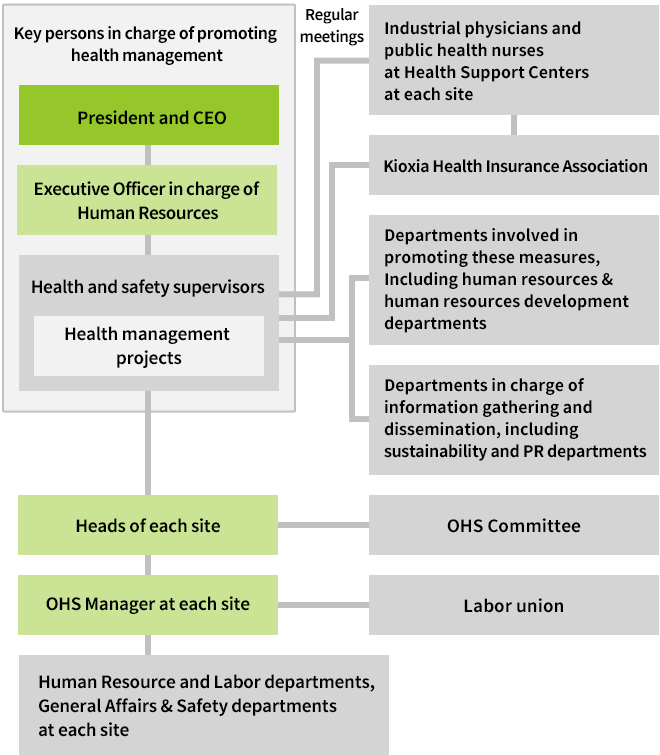

Organizational Structure of Health Management

The President and CEO of Kioxia Holdings Corporation and Kioxia Corporation has ultimate responsibility for the promotion of health management. In 2023, Kioxia Corporation reorganized its approach in this area, allowing each level and organization to fulfill its role in promoting employee health though a top-down approach, as shown in the diagram below.4

With the Health and Safety Section of the company’s Human Resources and Administrative Division as the secretariat, activities, measures and policies are discussed at regular meetings with the Health Support Center, which deploys industrial physicians and public health nurses at each of our sites. In addition, our management is committed to focusing on health-related issues, with the company, labor union, and health insurance union working together to promote healthy activities and lifestyles.

In the future, we will expand our health management initiatives to other group companies.

4 Currently at Kioxia Corporation, the President and CEO also promotes health management at Kioxia Holdings Corporation.

Organizational Structure for Health Management at Kioxia Holdings Corporation and Kioxia Corporation

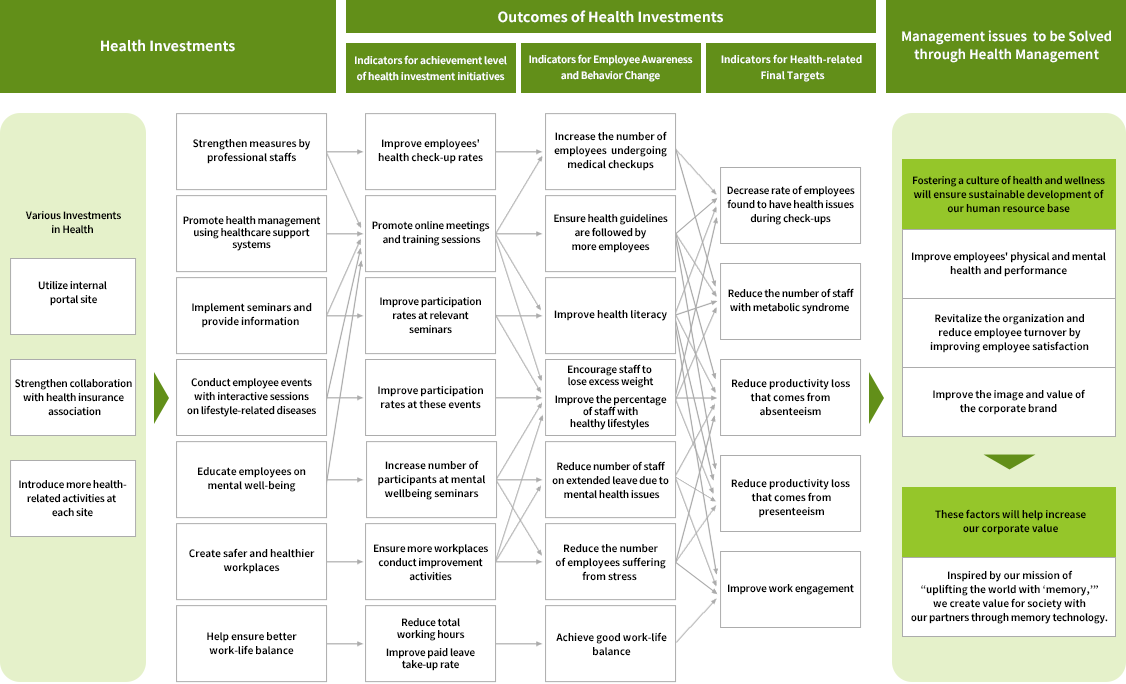

Health Management Strategy and Processes

Kioxia Group has formulated a health management strategy and processes in order to clarify issues and areas related to health management, implement measures to address these issues, and continuously implement the PDCA cycle while verifying the effectiveness of each measure.

Recognizing the importance of workplace engagement in terms of promoting our employees‘ physical and mental health and improving their performance, we will continue to promote health-related measures for them.

To ensure that employees can work for many years in good health and spirits, we will strategically promote employee health and foster a culture of good health aimed at making it easier and more rewarding to work. By doing so, we aim to enhance our corporate value in a sustainable manner.

Health Management Strategy Map5

5 This covers Kioxia Holdings Corporation and Kioxia Corporation. The below targets, initiatives and results are based on this strategy map.

Targets

To promote health management, we have set goals in three areas: (1) prevention of the onset and spread of lifestyle-related and other diseases, (2) prevention of stress-related diseases, and (3) creation of more lively workplaces.

(1) Improve lifestyles by enhancing health literacy.6 Prevent the onset and spread of lifestyle-related diseases.

(2) Prevent stress-related conditions such as declines in mental well-being

(3) Achieve a good work-life balance. Create more lively workplaces through improved employee engagement

To achieve these goals, in July 2024 we set mid-term targets to be achieved by FY2028.

6 The knowledge, willingness, and ability to obtain, understand, evaluate, and use health-related information

Health and Productivity Management Initiatives

We pursue the following initiatives in order to create an environment where employees can work in good mental and physical health. Each business site also proactively implements its own measures.

- We have established processes whereby physicians are deployed to comment on the results of medical check-ups covering lifestyle-related diseases such as high blood pressure and high blood sugar levels, allowing for consultations with medical personnel and intervention by physicians. In this way we aim to reduce the number of employees who leave the company as a result of absenteeism, extended leave or illness.

- We have set up a mental health consultation service and make its existence known to all employees. We also provide various training programs aimed at preventing stress-related illnesses.

- We are promoting collaborative health programs7 with health insurance societies to improve employees’ health literacy and to prevent or treat any instances of metabolic syndrome.

7 These are aimed at preventing disease and promoting good health for employees and their families in conjunction with companies and insurers.

Example Initiatives

Kioxia Holdings Corporation and Kioxia Corporation conducted the following key initiatives in FY2024:

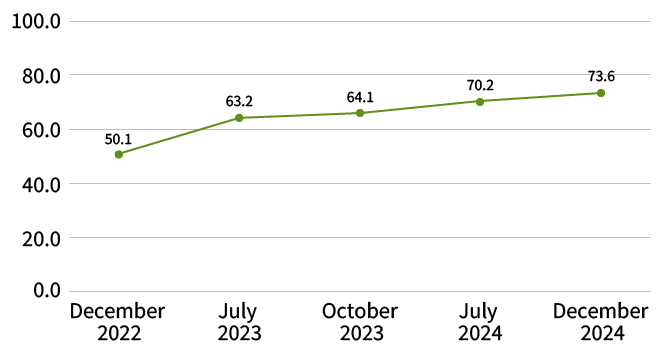

Health Promotion Event during Health Enhancement Month: “The Benefits of Three Daily Meals and Nutritional Balance”

Period: December 2 – December 15, 2024

Number of participants: 5,657 (participation rate: 73.6%)

At Kioxia Corporation’s Yokkaichi Plant, initiatives are being implemented to help employees adopt healthy eating habits. They incorporate eating three meals a day with a balance of nutritious ingredients, thereby helping to prevent lifestyle-related diseases. In December 2024, a so-called “enhancement month,” the cafeteria offered a menu rich in seasonal vegetables developed in collaboration with employees. Additionally, measurements of vascular age, blood pressure, and body composition were taken, and a quiz was organized to help employees determine their recommended daily vegetable intake (350 g), aiming to improve their health literacy. These initiatives have been well received, and participation rates have increased with each event.

The Walking Event

Date: November 11, 2024

Number of participants: 640 (participants’ satisfaction rate: 96.2%)

Kioxia Corporation’s Yokkaichi Plant co-hosted its annual walking event in collaboration with the Kioxia Labor Union Yokkaichi Branch. Two walking courses—2 kilometers and 5 kilometers— were set up in Kasumigaura Park, adjacent to Yokkaichi Dome, allowing employees to walk at their own pace with family members and teammates. At the finish line, participants were welcomed with a variety of events commemorating the fifth anniversary of the company name change and were presented with completion certificates and lunch. A prize drawing further enlivened the event, with the plant manager, the union chairman, and the chairperson of the Health Promotion Committee presenting prizes and helping to create a festive atmosphere.

After the event, participants shared positive feedback. Comments included, “Without events like this, I don’t really feel motivated to go walking! It was a great opportunity,” “I enjoyed the opportunity to interact with people from other departments,” and, “I appreciated the many fun and safe activities for children.”

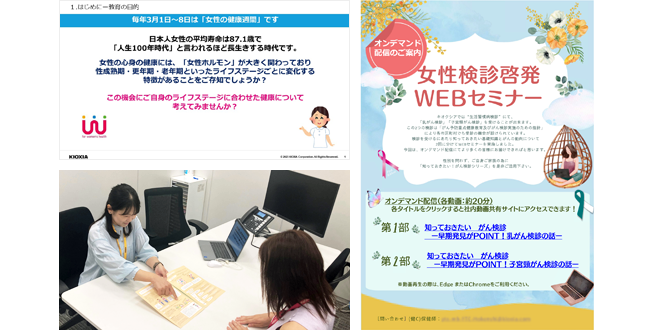

Measures to Address Women's Health Issues

Number of participants in FY2024

E-learning: 1,007 participants (participation rate 99.9%)

Seminars: 351 participants

Kioxia Holdings Corporation and Kioxia Corporation have implemented e-learning and seminars covering basic knowledge of cancers specific to women, the importance of health screenings, and the impact of female hormones on health. These learning opportunities are designed to encourage female employees of all ages to undergo health screenings and attend medical facilities.

Additionally, to make consultations easier for female employees, a consultation desk has been established where they can receive health advice from female gynecologists and nurses. Seminars have also been held to increase mutual understanding between men and women.

Mental Health Seminars for Managers

Number of participants in FY2024

2,031 (participation rate: 78.7%)

Officers and division managers participated in either in-person or online sessions, while section managers took on-demand video courses.

A guest speaker was invited to give a lecture for managers of Kioxia Group in Japan on the topic “Impact of Workers’ Sleep on Health and Productivity.”

Of the participants, 99.6% indicated they had gained a better understanding of the importance of sleep, and 97.9% found the session informative. In addition, 94.4% responded positively, saying they could apply what they learned in their own workplace.

Changes in Individual Indicators

*Table can be scrolled horizontally.

| Indicator | Results | Target |

|||

|---|---|---|---|---|---|

| FY2021 | FY2022 | FY2023 | FY2024 | FY2028 | |

| Percentage of employees undergoing annual health check-ups | 100% | 100% | 100% | 100% | 100% |

| Percentage of employees with abnormal findings from health check-ups | 33.2% | 31.1% | 31.9% | 30.8% | Less than 30.0% |

| Percentage of employees undergoing detailed examinations after annual health check-ups | — | 39.4% | 79.2% | 78.3% | 100% |

| Percentage of employees receiving health guidance | — | 68.4% | 100% | 100% | 100% |

| Percentage of employees with metabolic syndrome (aged 40 and over)14 | 20.6% | 19.0% | 20.2% | 20.5% | Less than 18.0% |

| Percentage of employees with appropriate body weight (BMI 18.5–25) | 61.0% | 61.7% | 62.6% | 61.9% | 66.0% or more |

| Percentage of employees with regular exercise habits (at least 5,000 steps per day) | 35.5% | 36.7% | 44.4% | 50.5% | 55.0% or more |

| Percentage of employees getting sufficient rest through sleep | 73.6% | 75.2% | 72.9% | 71.0% | 80.0% or more |

| Percentage of employees who smoke | 23.2% | 20.8% | 21.6% | 21.3% | Less than 18.5% |

| Percentage of employees undergoing stress check examinations | 96.8% | 95.7% | 97.2% | 97.1% | 98.0% or more |

| Percentage of employees classified as high-stress (based on company standards)8 | 4.8% | 5.0% | 4.4% | 4.3% | Less than 4.0% |

| Percentage of employees absent from work for one month or more due to mental illness | — | 1.24% | 1.29% | 1.62% | Less than 1.0% |

| Absenteeism9 | — | 10.6% | 9.2% | 9.5% | Less than 7.0% |

| Presenteeism10 | — | 85.7% | 84.7% | 84.1% | 86.0% or more |

| Work engagement11, 14 | — | — | 2.45 points | 2.44 points | 2.52 points or more |

| Health literacy12 | — | 3.46 points | 3.48 points | 3.52 points | 3.59 points or more |

| Job satisfaction13 | — | 2.23 points | 2.29 points | 2.25 points | Less than 2.20 points |

- 8 The percentage of employees identified as having high stress levels during stress checks (based on company-devised standards).

- 9 The percentage of employees who took 8 or more days off due to illness or health-related issues.

- 10 A self-assessment of work performance over the past four weeks, with 100% being the performance achievable when not experiencing illness or injury.

- 11 Average scores based on respondents’ level of agreement with the following two statements: “I feel energized when I am working” and “I take pride in my work” during stress checks. Responses were scored as follows: Strongly Agree: 4 points, Agree: 3 points, Disagree: 2 points, Strongly Disagree: 1 point.

- 12 The average score using the Communicative and Critical Health Literacy scale.

- 13 Average scores based on respondents’ level of agreement with the statement “I am satisfied with my job” during stress checks. Responses were scored as follows: Strongly Agree: 1 point, Agree: 2 points, Disagree: 3 points, Strongly Disagree: 4 points.

- 14 Key Goal Indicator

Certified as an Excellent Health and Productivity Management Corporation

In March 2025, Kioxia Holdings Corporation and Kioxia Corporation were certified for the second consecutive year as an “Excellent Health and Productivity Management Corporation (Large Corporation Category)” by the Ministry of Economy, Trade and Industry and the Japan Health Conference, specifically recognizing our active implementation of health management practices. The companies were also certified for the first time under the “Sports Yell Company” program by the Japan Sports Agency.

For other health and safety performance statistics, please see the following Social data.