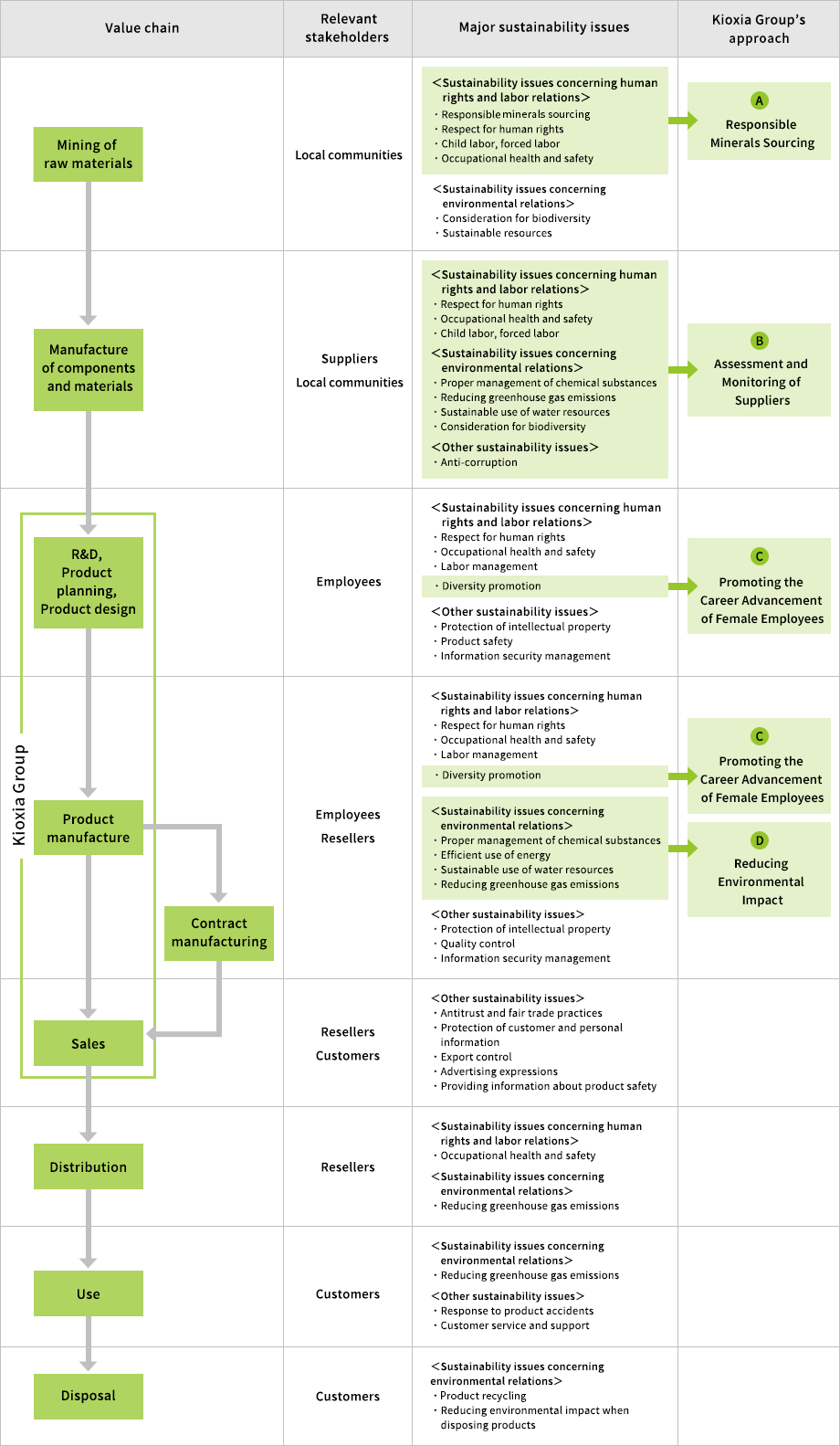

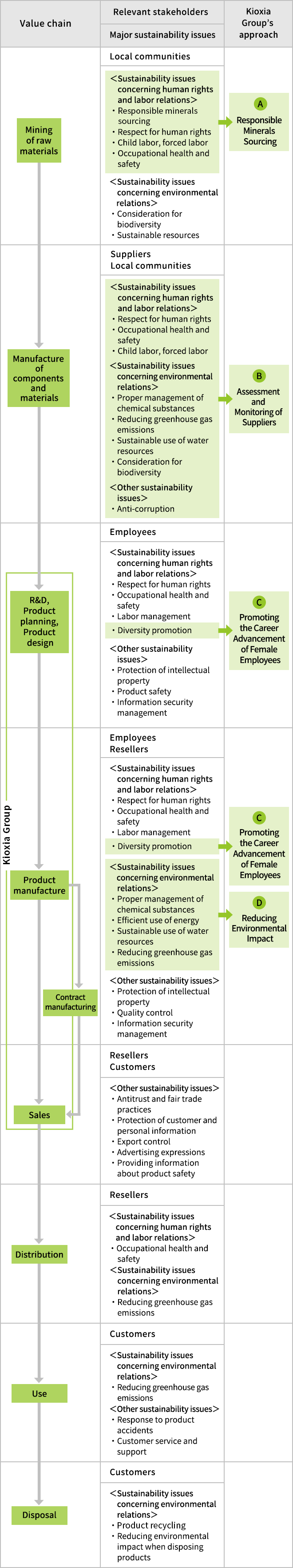

Major Sustainability Issues and Initiatives in the Value Chain

Due to the fact that the structure of our various business segments differs and their value chains and stakeholders vary, Kioxia Group performs mapping and analyzes sustainability challenges and risks for each segment, doing our utmost to avoid and reduce risks.