Sustainable Supply Chain

Stakeholder interest in corporate social responsibility across supply chains is growing year by year. Kioxia Group is committed to ensuring fair business practices in its Standards of Conduct, and has designated sustainable supply chains as priority areas of focus in terms of ensuring the Group’s medium- to long-term growth, and we call these Sustainability Materiality.

By collaborating with suppliers, we conduct business with due consideration of supply chain issues, such as the human rights of workers, occupational health and safety, and the environment, with the aim of reducing business risks and achieving sustainable procurement.

Kioxia Group’s Supply Chain

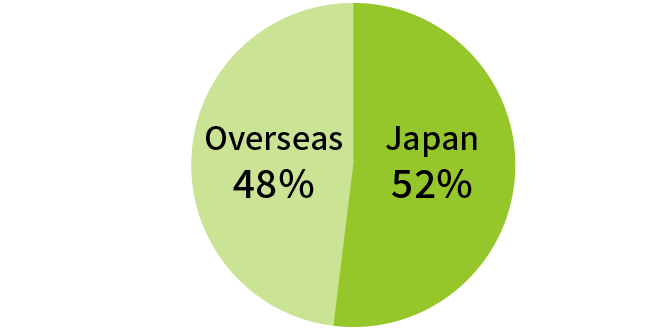

Breakdown of Procurement Spend by Region (FY2024)

Kioxia Group procures a variety of raw materials and resources from suppliers in different countries and regions. In FY2024, we had relationships with approximately 650 suppliers, and overseas suppliers accounted for 48% of our total procurement.1

- 1 "Overseas suppliers” includes procurement from Japanese subsidiaries of foreign-owned companies

Kioxia Group Procurement Policy

Kioxia Group strives to manage our supply chain and promote sustainable procurement throughout these supply chains by complying with the procurement-related laws and regulations of each country or region and their social norms, as well as by building sound relationships with suppliers based on mutual understanding and trust.

We require our suppliers to comply with and implement the Kioxia Group Procurement Policy, and we call for responsible business practices throughout our supply chain.

In addition to the Kioxia Group Supply Chain Code of Conduct governing the promotion of responsible business, we have established Kioxia Group Green Procurement Guidelines covering the use of chemical substances, and the Kioxia Group Responsible Minerals Sourcing Policy, which references mineral sourcing. We have informed all relevant suppliers of these policies and instructed them to take appropriate action in order to comply with them. These policies and guidelines are available in multiple languages, including Japanese and English.

Structure for Supply Chain Management

Kioxia Group is committed to conducting appropriate transactions with its suppliers and to robust supply chain management. Kioxia Corporation has dedicated the Procurement Department as the head office. It coordinates with relevant sections within Kioxia, such as the Supply Chain Management Department, the Sustainability Division, environment related sections, the Human Resources and Administration Division and group companies in order to address issues regarding human rights, labor, safety, the environment, and other business risks, including those of suppliers. Important issues are submitted to the Sustainability Committee for consideration as needed.

Participation in Industry Groups and Initiatives

Kioxia Holdings Corporation joined the Responsible Business Alliance (RBA) in 2021 in order to fulfill our social responsibilities across our global supply chain in such areas as labor practices, occupational health and safety, environmental protection, and ethics. As a regular member of the Alliance, we conduct business responsibly in accordance with the RBA Code of Conduct by implementing our own sustainability initiatives and requiring our suppliers to do the same.

In addition, Kioxia Group promotes the responsible procurement of minerals across the Group. Under the umbrella of the RBA, Kioxia Holdings Corporation participates in the Responsible Minerals Initiative (RMI) and Kioxia Corporation has joined the Responsible Minerals Trade Working Group of the Japan Electronics and Information Technology Industries Association (JEITA).

Assessment and Monitoring of Suppliers

New Supplier Assessment

When commencing business with a new supplier, we make them aware of our policies governing sustainable procurement, as well as our Group’s overall procurement policies and Supply Chain Code of Conduct. Before conducting any business with them, we first confirm that the supplier’s occupational health and safety measures, environmental and process management structures, legal compliance standards, and management standards, etc., meet the standards of Kioxia Group.

Supply Chain Monitoring

Prior to continuing business with an existing supplier, we use references such as the current scale of our business with them, and ask them to conduct a self-assessment survey using a format (SAQ)2 provided by the RBA (Responsible Business Alliance). This enables us to confirm the status of the supplier’s compliance with the RBA Code of Conduct and facilitates rigorous management of our supply chain. Interviews by our procurement managers are conducted with suppliers determined by the RBA-SAQ to be of high risk, and where necessary, we will request suppliers to implement corrective measures, such as undergoing an RBA third-party audit. In addition, we check the management status of suppliers’ manufacturing sites by means of quality audits, requesting improvements and providing support for the implementation of these where necessary.

- 2 Self-Assessment Questionnaire (SAQ) provided by the RBA: This contains questions about labor practices, occupational health and safety measures, the environment, ethics, and management systems. We use two types of SAQ: Corporate, which covers companies in their entirety; and Facility Risk, which focuses on individual factories.

Supply Chain Monitoring Results (FY2024, Kioxia Group in Japan)

* Table can be scrolled horizontally.

| No. of Surveyed Companies | No. of Responses | Results of Risk Assessment (No. of Cases) | Requests for Corrective Measures (No. of Cases) | |||

|---|---|---|---|---|---|---|

| Low Risk |

Medium Risk |

High Risk |

||||

| RBA-SAQ3 (Corporate) |

74 | 74 | 61 | 13 | 0 | 0 |

| RBA-SAQ3 (Facility Risk) |

74 | 155 | 75 | 77 | 3 | 0 |

- 3 RBA-SAQ responses from RBA Online

Responsible Minerals Sourcing

Given Kioxia Group’s role in the supply chain of its client companies listed on U.S. stock exchanges, following the enactment of Section 1502 of the U.S. Dodd-Frank Wall Street Reform and Consumer Protection Act (the Dodd-Frank Act) in 2010, we ensured smelters in our own supply chain were investigated by our suppliers to confirm that proceeds from the sales of tin, tantalum, tungsten, and gold (commonly known as 3TG) from the Democratic Republic of the Congo or neighboring countries are not being used as a source of funds for anti-social forces.

Since March 2021 Kioxia Group has been promoting the responsible procurement of minerals from other countries and regions as well. The Kioxia Group Responsible Minerals Sourcing Policy stipulates that Kioxia Group will prohibit use as raw materials 3TG or cobalt obtained from other conflict-affected and high-risk areas (commonly known as CAHRAs) where inhumane acts such as human trafficking, slavery, forced labor, child labor, abuse, or war crimes are suspected.

Structure of Kioxia Group’s Minerals Sourcing Activities

Kioxia Corporation has dedicated the Procurement Department as the headquarters. It coordinates with relevant sections within the Group, such as supply chain management, sales, technology, and IT in order to pursue procurement activities in accordance with the Kioxia Group Responsible Minerals Sourcing Policy, and raises issues to the Sustainability Committee for discussion as necessary.

Minerals Sourcing Survey

Kioxia Group investigates the use by mineral smelters in our supply chain of minerals they deliver to the Group, such as 3TG and cobalt. We require that suppliers procure all materials from Responsible Minerals Assurance Process (RMAP) smelters certified by the RMI (Responsible Mineral Initiative), and also request that suppliers identify applicable smelters in the supply chain if 3TG mineral procurement is conducted in the Democratic Republic of Congo, neighboring areas or other conflict or high-risk areas.

In FY2024, Kioxia Group in Japan requested 71 suppliers that may have used 3TG minerals to conduct a smelter survey using the Conflict Minerals Reporting Template (CMRT) produced by the RMI. Following requests from our stakeholders, we added cobalt to the list of minerals surveyed, and conducted smelter surveys at 22 suppliers using the RMI Extended Minerals Reporting Template (EMRT) in FY2024.

Minerals Procurement Monitoring Results (FY2024, Kioxia Group in Japan)

* Table can be scrolled horizontally.

| Survey Date | No. of Surveyed Companies | Survey Results (Percentage of Responses) | Suspension of Business, etc. | ||||

|---|---|---|---|---|---|---|---|

| No. of Responses | No. of Conformant4 | Survey Continued | Failure of Corrective Measures | ||||

| CMRT Surveys (3TG) | End of March 2025 | 71 (Percentage of responding companies: 100%) |

129 | 113 (88%) |

16 (12%) |

0 (0%) |

0 |

| EMRT Surveys (Cobalt) |

End of March 2025 | 22 (Percentage of responding companies: 100%) |

33 | 21 (64%) |

12 (36%) |

0 (0%) |

0 |

- 4 Request for due diligence by suppliers that procured minerals from smelters that are not RMAP-compliant

Green Procurement

Kioxia Group’s Environmental Policy outlines our environmental contribution to the realization of a sustainable society.

Kioxia Corporation has established a Green Procurement Working Group under the auspices of environment, quality control, and procurement sections, to work on green procurement, with the aim of contributing to the realization of a sustainable society. The company has also formulated Green Procurement Guidelines, which outline our management standards and contain specific requirements for suppliers regarding the selection of materials with a low environmental impact and the use of chemical substances. We periodically update the guidelines to reflect issues such as changes in the laws and regulations of individual countries or regions, or in response to customer requests.

We also conduct a thorough assessment of the environmental impact of chemical substances from the design and development stage, and use materials with a low environmental impact as part of our efforts to reduce our own environmental footprint.

Through these initiatives, we will continue to collaborate with our suppliers on issues affecting environmental conservation, aiming to contribute to the realization of a better global environment.

Sustainable Procurement Training for Employees

To ensure compliance with our procurement processes, Kioxia Group in Japan provides basic training to all executives and staff covering the country’s Subcontract Act and related laws. In addition, the Procurement Department provides specialized training on compliance with relevant laws, regulations and rules to employees.

In addition, with the aim of realizing a sustainable supply chain, supply chain management, sales, and technology sections regularly conduct training on global social issues in the supply chain such as human rights and labor, the RBA Code of Conduct, and the sustainable procurement activities of the Group.

How We Address Supply Chain Risk

Kioxia Group requires suppliers to make improvements and take appropriate measures if they are found to have violated our procurement policies or Supply Chain Code of Conduct, if sustainability-related risks are identified in the operations of a supplier or supply chain, or if there is a new law or regulation or social requirement necessitating a response.

While we will offer corrective guidance and support in such cases, we will suspend business with them in cases where corrective measures are judged to be difficult to implement.

In FY2024, there were no cases where business with a supplier was suspended due to risks related to sustainability.

Securing Supplies in Accordance with Business Continuity Management Procedures

Kioxia Group strives to engage multiple suppliers and works closely with them in order to avoid interruptions to business in the event of emergencies such as natural disasters, accidents, pandemics or geopolitical risks. Under our business continuity management (BCM) regulations,5 Kioxia Corporation and Kioxia Group’s affiliated companies6 ensure they are fully aware of the status of their supply chains during normal times, allowing them to swiftly grasp the impact in the event of an emergency. We have also established a framework for cooperation aimed at achieving the early recovery of services. Additionally, we will strive to develop our business continuity planning through BCP assessments at major suppliers.

- 5 Comprehensive and integrated management of business continuity, including the formulation of countermeasures, their implementation, operation and review, and continuous improvements aimed at minimizing the impact on the organization, without the need for a suspension of business operations in the event of an emergency, or recovering in a short period of time if business is suspended.

- 6 20 affiliates of Kioxia Group in Japan and overseas (as of March 2025)