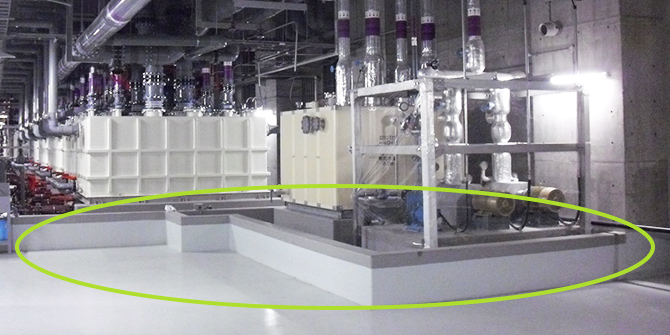

Prior to constructing manufacturing facilities, Kioxia Group considers the impact of the construction on the surrounding environment, conducts an environmental assessment, and takes all necessary precautions. Additionally, after construction is completed, we monitor various parameters in the surrounding environment such as noise and wastewater levels, and conduct surveys of the ecosystem to ensure that the surrounding environment has not been adversely affected by the construction.

The construction of Kioxia Iwate Corporation’s second fabrication facility (Fab2) was the largest project of its kind in Kitakami City, where the company is located. Careful measures were taken during construction to mitigate potential impacts on the surrounding environment. To ensure that dust, noise, wastewater, waste, lighting, soiling of road surfaces, and other construction-related impacts did not affect the daily lives of local residents, we worked closely with construction contractors from the preparatory stage through to project completion. We conducted bi-weekly environmental patrols, installed temporary noise barriers and wastewater treatment facility at the construction site, thereby preventing pollution and accidents in the surrounding area.