We use our memory technology to innovate digital technology and help make people’s lives safe, secure, convenient and comfortable, thereby creating value for society.

SDG-Related Topics

Kioxia Group Businesses That Contribute to Society

Here, we will introduce specific examples that show how Kioxia Group’s businesses have contributed to addressing social issues and achieving some of the UN’s Social Development Goals.

Making Every Bit of Data More Widely Available

Urban areas to which people are increasingly moving need to provide lifestyles that are safe and convenient and that allow those people to maintain a high quality of life. To this end, the spread of flash memory and SSDs has helped provide people with internet access that is available anytime and anywhere. For example, the spread of the internet has made it possible for people to access a whole range of information on a smartphone even when they are outside. It also allows us to communicate with people all over the world from the home or office using a PC or tablet. In addition, recording technologies such as image authentication and dashboard cameras have improved safety and security.

By manufacturing flash memory and SSDs with increased capacity and improved performance, Kioxia Group is helping more people lead better lives.

Leveling Up the World with Every Bit of Data

The worldwide concentration of populations in cities has led to the depopulation of surrounding rural areas and the emergence of lifestyle differences between the two. However, an environment offering internet access allows people to obtain the same information from anywhere using devices such as smartphones or tablets. The availability of internet access anytime and anywhere has led to an improved quality of life for people, and has also increased opportunities for work and for children’s education.

Enriching a New Ways of Life with Bits

The global COVID-19 pandemic forced us to make major changes to our lifestyles. When commercial activity and people’s movement were being greatly restricted worldwide, online communication became a means to connect people and things, bringing about changes in behavior that have persisted even after the pandemic. An environment in which the internet is accessible anytime and anywhere also helps people to work remotely, and facilitates online classes and other alternatives that help realize a new way of life.

Technological Developments That Support Cutting-Edge Science

In collaboration with Massachusetts Institute of Technology (MIT), Kioxia Corporation has been building signal processing systems for use in the field of neuroscience.

Research into the human brain requires high-speed analysis of large volumes of data. Kioxia Corporation helps promote brain research with its high-speed, large-capacity SSDs that are utilized for such analysis and help accelerate the research cycle.

Technological Developments That Support the Information and Communications Era

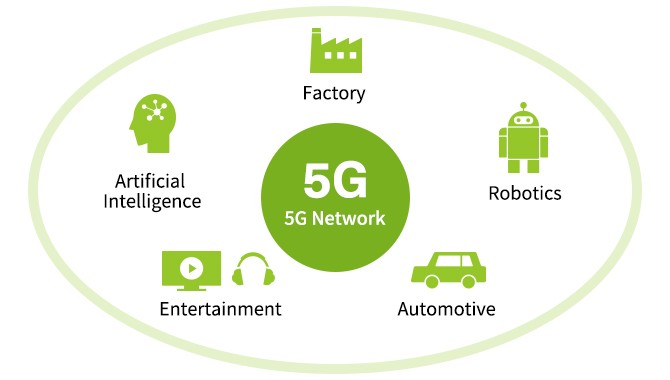

To support the information and communications era, Kioxia Group is pursuing cutting-edge research and development in fields such as self-driving vehicles, smart factories, robotics, and entertainment.

High-Efficiency Manufacturing

During the manufacturing of flash memory, including BiCS FLASH™, Kioxia Group collects huge amounts of real-time data from manufacturing equipment and transportation systems, and analyzes this data using AI technologies such as deep learning in order to shorten turnaround times. In this way, we can reduce the consumption of energy and materials, improve yield, and ensure a stable supply of high-quality products. The cutting-edge AI technologies supporting our smart factories have been developed not just through the use of Kioxia Group’s proprietary technologies, but also through open innovation with our partners. Kioxia Group will continue to utilize AI technologies to maintain and improve productivity, deploying smart factories that contribute to the development of a sustainable society.

Yokkaichi Plant

Kitakami Plant

Transportation equipment inside the clean room

Waste Reduction and Recycling

Kioxia Group’s plants have been expanded in order to meet increasing demand from the market. As a result, the amount of waste we generate is rising every year. However, we are striving to make effective use of resources with the aim of reducing environmental impact throughout our supply chain. As an example, we are actively working to reduce the use of chemicals and gases by recovering and recycling waste generated during manufacturing, improving manufacturing processes, and using packaging with reduced environmental impact.

Greenhouse Gas Net-Zero Emissions

At Kioxia Group, we prioritize initiatives aimed at reducing greenhouse gas emissions, seeing this as one of our key management objectives. By FY2050, we aim to achieve net-zero in terms of our Scope 1 greenhouse gas emissions (direct emissions from our business sites), and in terms of Scope 2 emissions (those resulting from our use of purchased energy).

In order to achieve these goals, we will continue to install equipment that will eliminate the emission of perfluorocarbons (PFCs)—gases with high global warming potential—at all of our manufacturing facilities constructed since 2011. As for measures related to purchased energy, the group is procuring and installing energy-efficient manufacturing equipment and power equipment. In FY2022, we commenced the introduction of solar power generation systems at our plants. We are also moving forward with the procurement of renewable energy certificates in Japan. We will continue our efforts to address climate change.

Efforts to Improve Product Energy Consumption Efficiency

As we believe that providing high-capacity and energy-efficient flash memory and SSD products helps achieve a low-carbon society, we are making a range of efforts in this area.

For example, we are making efforts to improve the energy consumption efficiency per GB data processing of our products when they are in use. We are also working to reduce the amount of electricity and materials used during manufacturing.

Helping to Create a Sustainable Society with Cutting-edge Technology

Our mission is “uplifting the world with ’memory.’” This mission was established after discussion between our management and our employees about the kind of company we want to create in the future.

Based on this mission, we will continue to work together with our partners to help more people lead convenient and comfortable lives, address a variety of social and environmental challenges, and contribute to the development of a sustainable society. In order to achieve this, we will work with these partners to further increase the capacity, performance and efficiency of our flash memory and SSD products.